TEACHER TALKS OF "APPLICATIONS FOR CERAMIC"

-Prof, a client asked me a few cups and dishes for an event, and planned to do sublimated, but not anything like that, it is very difficult?

"Look, to sublimation in ceramic cups will require preparation, including inkjet printer cartridges, new and special inks to print sublimation transfers, as well as a special press 11 oz cups, ITESDI or presses, you can see in the video

"And no one maquila transfers, as they do where tabloids and cards printed?

"No, most people print their own transfers Sublimation

"Then I have to make a good investment to enter the business of ceramic decoration

" Not necessarily, in ITESDI have a better option for those who want to enter this market, which incidentally, is growing every day more.

"That option is the Professor?

"Well, with the development of new laser digital printing techniques, combined with some papers for applications in ceramics, it is now possible to print the papers in digital laser

" And I can also put photos on mugs?

"As we know, the only limit on the digital printing is your imagination, so with this technique, you can put in the cups and plates, any image in full color and fully detailed

And the cups and plates, must be treated with a resin or polyester?

"As we have seen in the" Teacher's Talks "on the blog of sublimation inks are" gasified "being fixed image on the polyester layer that covers them, and without this layer is not possible impression, but it is only necessary in the case of sublimated mugs, not paper ITESDI

"And how the role for ceramics?

-This paper is coated with a varnish, which is that "receives" the laser printer toner, which is a powder, no liquid ink, which allows a better definition of the quality of the image.

This coating, once applied and put into the home electric oven, practically "melts" with the ceramic substrate, forming a "sandwich" in which the toner is in the middle, which gives a high resistance to washing.

"Then why do not need cups treated with resins or polyesters.

"Yes, and obviously any items of pottery such as cups, plates, tiles or tiles can be decorated with printed on paper applications ITESDI

" And the costs are equal to or higher if you do sublimated mugs?

"On the contrary, by not having to use cups treated, or having to invest in inkjet printer cartridges and ink to sublimate, or presses, that makes the set of cups with paper ITESDI, whether economic, giving you a greater profit margin, and therefore more competitive in the market

"And how many cups I can make per hour?

-In ITESDI, from applications to have printed and cut, decorate an average of 30 cups in 2 hours, including baking, but as always I tell .... "Practice makes perfect"

-Y has a graphical guide on how to decorate the cups?

-Better yet, I have a video I took during a class on "Integrated Creative Solution", a Tijuana company, which among other things, gives the design and printing service digital, check it out and really simple objects it is decorated with paper cups ITESDI

"And as I can take on the role ITESDI?

-Czech first video, and send an email with your questions to itesdi@hotmail.com , and now you're ready, I'll tell you how to acquire the test kit and shipping cost

-Prof, give me a preview of the cost of paper, to see if I should

-OK, look, a sheet of letter size paper ITESDI, costs an average of 3.50 dollar and applications can print 6 cup 11oz. on the one hand, the impression has an average cost of $ 1, giving you a cost of 0.75 of a dollar per application, plus the cost of the cup is on average 1.50 dollars, and if we round to 0.25 the application itself (light, time of application, gas, water, etc) gives an approximate total cost of 2.50 dollars, when the cup pure treated to sublime, we sell them blank 2.50 dollars, not counting the other expenses of production

"Well it sounds very interesting and productive

-Asi is, check out the video and tell me what you think

Profe-Ok, I'll do and I contacted you

-Sale, and always remember that .. .. "THE Practice makes perfect "

Wednesday, July 22, 2009

Tuesday, March 24, 2009

Hollywood Waxing Clip

TRANSFERS AND TEXTILE INKS FOR THE CLASSES OF TEACHER

-Prof, which I use for ink transfer on silk screening for shirts?

" As we have mentioned before, ink manufacturers always want us believe that there is a plastisol ink for each application, and some additives, we sell the same ink but with different classification and logic, with different prices

"Then the ink is the same for shirts and transfers ?

-Asi is, only to make transfers, you can use a little more closed meshes, and logic, you should add a little conditioner to the ink to make it a little more fluid

"I can add some solvent to make it more liquid?

-plastisol ink unlike other inks contain no solvents, so if you add some gas solvent such as gasoline or white gas, only affected the consistency of the ink in time, since the evaporation of the gasoline be re-doing "paste" and you tapara the mesh is indicated conditioner.

-What role should I use and where I buy it?

-As mentioned in the talk "PRINTING TRANSFERS" of 23/11/2008:

"Transfers Textiles have been developed since muchisisimo, and originally were made on wax paper, the problem was that if they spent some days and had not applied, the wax paper and ink integrated with and not taking off, what happens if you print it on paper or vegetal.Ya albanene with your transfer paper or "French paper" designed transfers to offset these were very peak in the 80's, especially with photographs of artists, because they printed a selection of color in this system (offset) and then silkscreen printed in a white cake in a mesh closed but not used or the adhesive or adhesive powder liquido.De fact, the use of powder is not essential, it is good to use it, but if you use correct temperature and pressure, there should be no problem even without polvo.Si you look at paper, has a side a little more glossy, which is suitable for offset printing, screen printing but there is no difference, the two sides work well "

you can find paper in your local paper or you can write to itesdi@hotmail.com if not available in your area, and I can send you

-What is the difference of stamping by the transfer and print directly to the garment?

-direct printing, allows ink to penetrate the tissue, and vulcanized, be an integral part of it, while the transfer does not penetrate well, and the passage of time can "crack"

Another difference is that if you have to do a design with different inks, you have to make a frame for ink, in addition to the limitation of the arms of your octopus and if you transfer, you can put multiple colors in one framework, only take care of your registration.

"And the durability of the garments is the same?

"That depends on how it is that has been vulcanized or transfers applied on clothes. As I mentioned in previous talks, there is a technique better than another, but rather is to master the one that best suits your needs in quantity, inks etc.

A garment vulcanized or cured to faulty transfer lasted less than a well implemented and visceversa

"Thanks Prof, I do my internship

"I hope this info will be useful and as always remember:

"Practice makes perfect"

-Prof, which I use for ink transfer on silk screening for shirts?

" As we have mentioned before, ink manufacturers always want us believe that there is a plastisol ink for each application, and some additives, we sell the same ink but with different classification and logic, with different prices

"Then the ink is the same for shirts and transfers ?

-Asi is, only to make transfers, you can use a little more closed meshes, and logic, you should add a little conditioner to the ink to make it a little more fluid

"I can add some solvent to make it more liquid?

-plastisol ink unlike other inks contain no solvents, so if you add some gas solvent such as gasoline or white gas, only affected the consistency of the ink in time, since the evaporation of the gasoline be re-doing "paste" and you tapara the mesh is indicated conditioner.

-What role should I use and where I buy it?

-As mentioned in the talk "PRINTING TRANSFERS" of 23/11/2008:

"Transfers Textiles have been developed since muchisisimo, and originally were made on wax paper, the problem was that if they spent some days and had not applied, the wax paper and ink integrated with and not taking off, what happens if you print it on paper or vegetal.Ya albanene with your transfer paper or "French paper" designed transfers to offset these were very peak in the 80's, especially with photographs of artists, because they printed a selection of color in this system (offset) and then silkscreen printed in a white cake in a mesh closed but not used or the adhesive or adhesive powder liquido.De fact, the use of powder is not essential, it is good to use it, but if you use correct temperature and pressure, there should be no problem even without polvo.Si you look at paper, has a side a little more glossy, which is suitable for offset printing, screen printing but there is no difference, the two sides work well "

you can find paper in your local paper or you can write to itesdi@hotmail.com if not available in your area, and I can send you

-What is the difference of stamping by the transfer and print directly to the garment?

-direct printing, allows ink to penetrate the tissue, and vulcanized, be an integral part of it, while the transfer does not penetrate well, and the passage of time can "crack"

Another difference is that if you have to do a design with different inks, you have to make a frame for ink, in addition to the limitation of the arms of your octopus and if you transfer, you can put multiple colors in one framework, only take care of your registration.

"And the durability of the garments is the same?

"That depends on how it is that has been vulcanized or transfers applied on clothes. As I mentioned in previous talks, there is a technique better than another, but rather is to master the one that best suits your needs in quantity, inks etc.

A garment vulcanized or cured to faulty transfer lasted less than a well implemented and visceversa

"Thanks Prof, I do my internship

"I hope this info will be useful and as always remember:

"Practice makes perfect"

Monday, January 12, 2009

Make A Dongle To Reset Bios

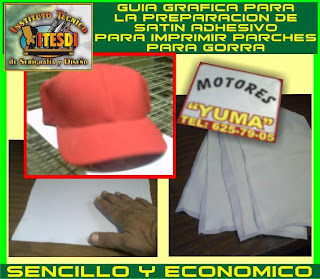

"ADHESIVE SATIN"

Profe, I made some transfers to caps, but when applied to the caps are broken because they bring a seam highlighted the center of the cap, I can do? Make

adhesive patches in satin, You will cover the seam without damaging the shuttle.

adhesive satin

But it sold only underground, and not many pieces the need to do but not always in my city

Well, make your own satin adhesive.

But I can do?

Generally, the adhesive satin is covered with a vulcanized rubbery base, which on contact with heat, acts as glue between the satin and the hat, what you would do would be to apply that based on the satin that sell homes in haberdashery or fabric.

But that base rate would be? is expensive? is for sale anywhere? as I apply?

We split, first of all, using the logic (greetings ADI), tell me that almost every product we have in the workshop, has these characteristics.

Well, the plastisol is based rubbery, but as the vulcanized? I have to carry specialized somewhere? This paper urges you to my client.

Let using logic, the word "vulcanized" derived from Vulcan, god of fire among the Greeks.

! Sure! refers to baking, or I can I print a plastisol cake and "cure"!

Okay, you're still using logic, so still and always will be easier to understand what I have often said, that the printing is and always will be a craft, which large companies try to make us look like something sophisticated and that raw materials have been developed only for very specific things, and it is not so

And because it has to be satin and no other material such as polyester or canvas?

The satin is a very manageable, that by giving it becomes rubbery base "body", but when sticking to the cap, just better to the curved shape.

And what kind of mesh I use a very open?

solid lumps one for you would be very useful, check out the mesh letter, give a better view Click for

And to apply the cake?

And to apply the cake?

Profe, I made some transfers to caps, but when applied to the caps are broken because they bring a seam highlighted the center of the cap, I can do? Make

adhesive patches in satin, You will cover the seam without damaging the shuttle.

adhesive satin

But it sold only underground, and not many pieces the need to do but not always in my city

Well, make your own satin adhesive.

But I can do?

Generally, the adhesive satin is covered with a vulcanized rubbery base, which on contact with heat, acts as glue between the satin and the hat, what you would do would be to apply that based on the satin that sell homes in haberdashery or fabric.

But that base rate would be? is expensive? is for sale anywhere? as I apply?

We split, first of all, using the logic (greetings ADI), tell me that almost every product we have in the workshop, has these characteristics.

Well, the plastisol is based rubbery, but as the vulcanized? I have to carry specialized somewhere? This paper urges you to my client.

Let using logic, the word "vulcanized" derived from Vulcan, god of fire among the Greeks.

! Sure! refers to baking, or I can I print a plastisol cake and "cure"!

Okay, you're still using logic, so still and always will be easier to understand what I have often said, that the printing is and always will be a craft, which large companies try to make us look like something sophisticated and that raw materials have been developed only for very specific things, and it is not so

And because it has to be satin and no other material such as polyester or canvas?

The satin is a very manageable, that by giving it becomes rubbery base "body", but when sticking to the cap, just better to the curved shape.

And what kind of mesh I use a very open?

solid lumps one for you would be very useful, check out the mesh letter, give a better view Click for

And to apply the cake?

And to apply the cake? As always I have a graphic guide you, even with the printing of the patch, dale click the image and check out the complete guide

luck and always remember: PRACTICE makes perfect

Subscribe to:

Posts (Atom)